Shellac printed circuit boards to protect the environment

Shellac printed circuit boards to protect the environment

"Green" electronics thanks to EMPA studies on the use of a well-known biomaterial for chip matrices: the... cochineal excrement

(Photo: EMPA)

The packaging "Intelligent" thanks to sensors that control the goods, especially perishables like the fruit and vegetables, on long transport routes they are a trend for the future.

However, printed and disposable electronics also cause serious problems: metals in printing inks are expensive and disposing of them in an environmentally friendly way is also very expensive, aggravating the problem of e-waste. A new solution, developed in Switzerland by researchers ofEMPA, aims to remedy this.

The first 127-qubit quantum processor is made-by-IBM

More precise, faster and cheaper with insect secretions

Scientists around the world have been working for years on the production of electrical and electronic circuits using additive processes such as the 3D robotic printing (the so-called "robocasting”) with great success, but now this attitude is becoming a problem.

The metal particles that make such "inks" electrically conductive are exacerbating the e-waste problem.

The problem is even more serious to the extent that the "garbage” of this type generated by the market is likely to increase in the future in view of the launch of new types of disposable sensors, some of which are and will be used only for a few days.

"Useless Waste", think Gustav Nystrom, head of the Cellulose & Wood Materials specialized research center of the Swiss Federal Laboratories is preferably used for Materials Science and Technology: “There is an urgent need for materials that balance electronic performance, cost and sustainability.”

To develop a ecological ink, the Swedish scientist's team has therefore set itself ambitious goals: metal-free, non-toxic and biodegradable. And, thinking of practical applications, too easily moldable and stable to humidity and moderate heat.

The first 127-qubit quantum processor is made-by-IBM

(Photo: EMPA)

Elongated plates of graphite mixed with soot particles

The researchers ofEMPA they chose the carbon cheap as a conductor material, as they recently highlighted in the magazine “Scientific Reports".

More precisely: elongated graphite plates mixed with tiny particles of soot, which establish an electrical contact between these same structures, all in a matrix made of a well-known biomaterial: shellac, which is obtained from the excrement or secretions of scale insects.

Le mealybugs or, improperly, coccidia (Coccoidea Handlirsch), are a superfamily of insects phytophagous included in the order of rhynchota (suborder homoptera, section sternorrhyncha). The name cochineal comes from Spanish cochineal ( "wood pig"). They are exclusively insects phytomyceous and constitute one of the most important groupings of harmful insects.

In the past, it was used to make music records; today it is used, among other things, as varnish for wood instruments and for lacquering nails.

Its benefits exactly match the desired profile of researchers. Furthermore, it is soluble in alcohol, thus an inexpensive solvent that evaporates after the ink is applied and dries.

So in Switzerland even mushrooms have learned to… write

A fluid material, when subjected to a lateral shear force

Despite these simple ingredients, the task turned out to be more challenging than expected. This is because, when used in the simple silkscreen printing or with the modern ones 3D printer, the ink must exhibit a behavior of shear thinning.

At "rest", the ink is quite viscous. But at the time of printing, when it is subjected to a lateral shear force, it becomes a little smoother, much like a non-drip wall paint that only acquires a smoother texture when applied by the force of the roller.

When used in additive manufacturing such as the 3d printing with a robotic arm, however, this is particularly difficult: an ink that is too viscous would be too hard – but if it becomes too liquid during printing, the solid components could separate and clog the printer's small nozzle.

Liquid robots like… cells to explore extreme environments

Passed tests in demanding processes like “robocasting”

To meet the necessary requirements, the researchers tinkered intensely with the formulation of their ink. They tested two sizes of graphite platelets: 40 micrometers and 7 to 10 micrometers long.

Many variations and attempts were also required in the mixing ratio of graphite e carbon black, because too much carbon black makes the material brittle with the risk of cracking and fissures when the ink dries.

The black of carbon o carbon black is a pigment, produced by the incomplete combustion of heavy petroleum products, which coal tar, tar obtained from ethylene cracking, or from vegetable fats and oils.

By optimizing the formulation and the relative composition of the components, the team ofEMPA was able to develop different variants of the ink, which can be used in different two-dimensional or three-dimensional printing processes.

“The biggest challenge was to get high electrical conductivity”Says Xavier Aeby, one of the researchers involved, “and at the same time form a gel-like network of carbon, graphite and shellac.”

Research center scientists Cellulose & Wood Materials have studied the practical behavior of this material in different phases.

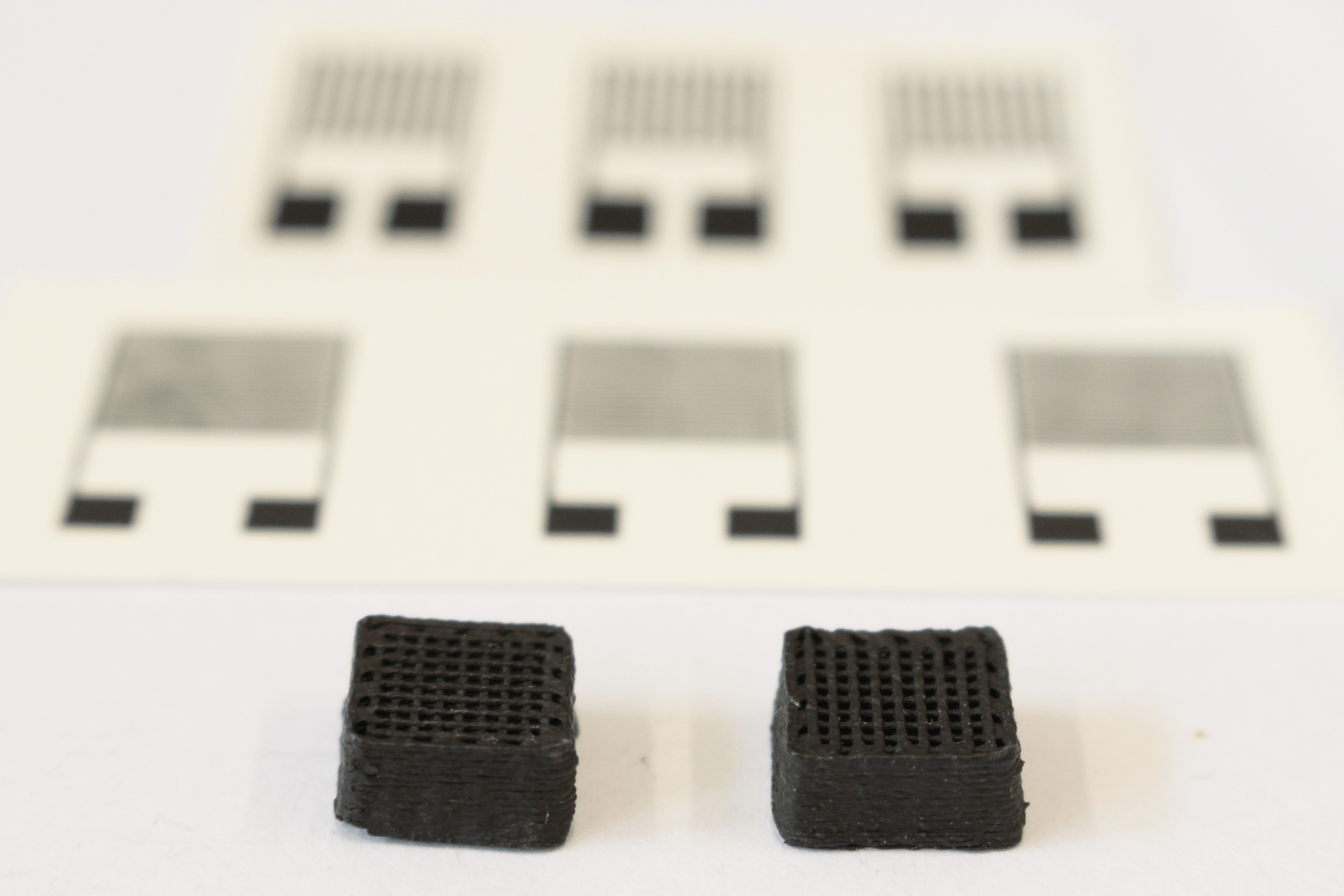

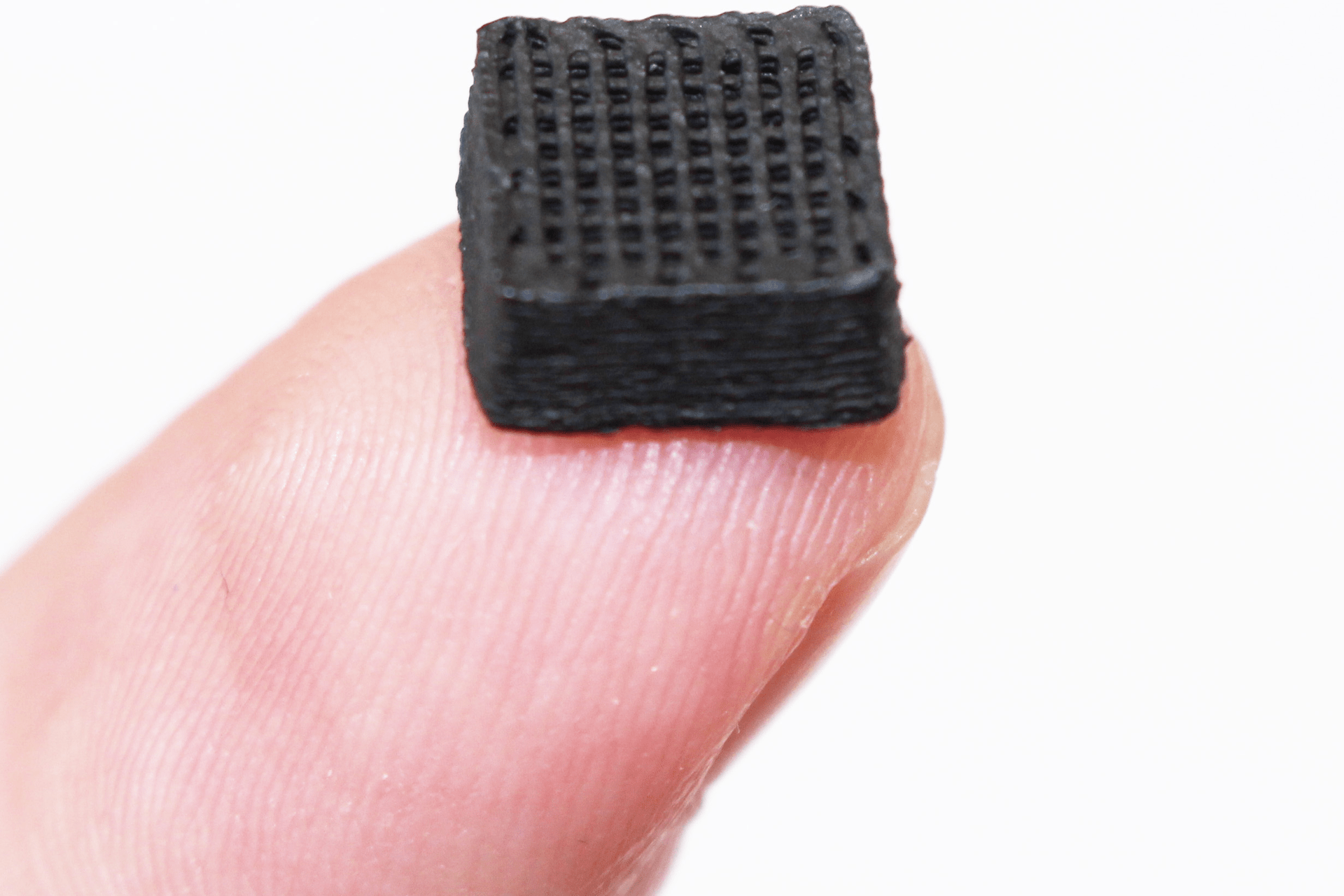

For example, with a small test cuboid: 15 overlapping grids from the Printer 3D, made of fine wires just 0,4 mm in diameter.

This proved that the ink was sufficient even for demanding processes such as “robocasting".

PSI in the future with a Big Data research division

(Photo: EMPA)

A PET strain sensor with electrical resistance

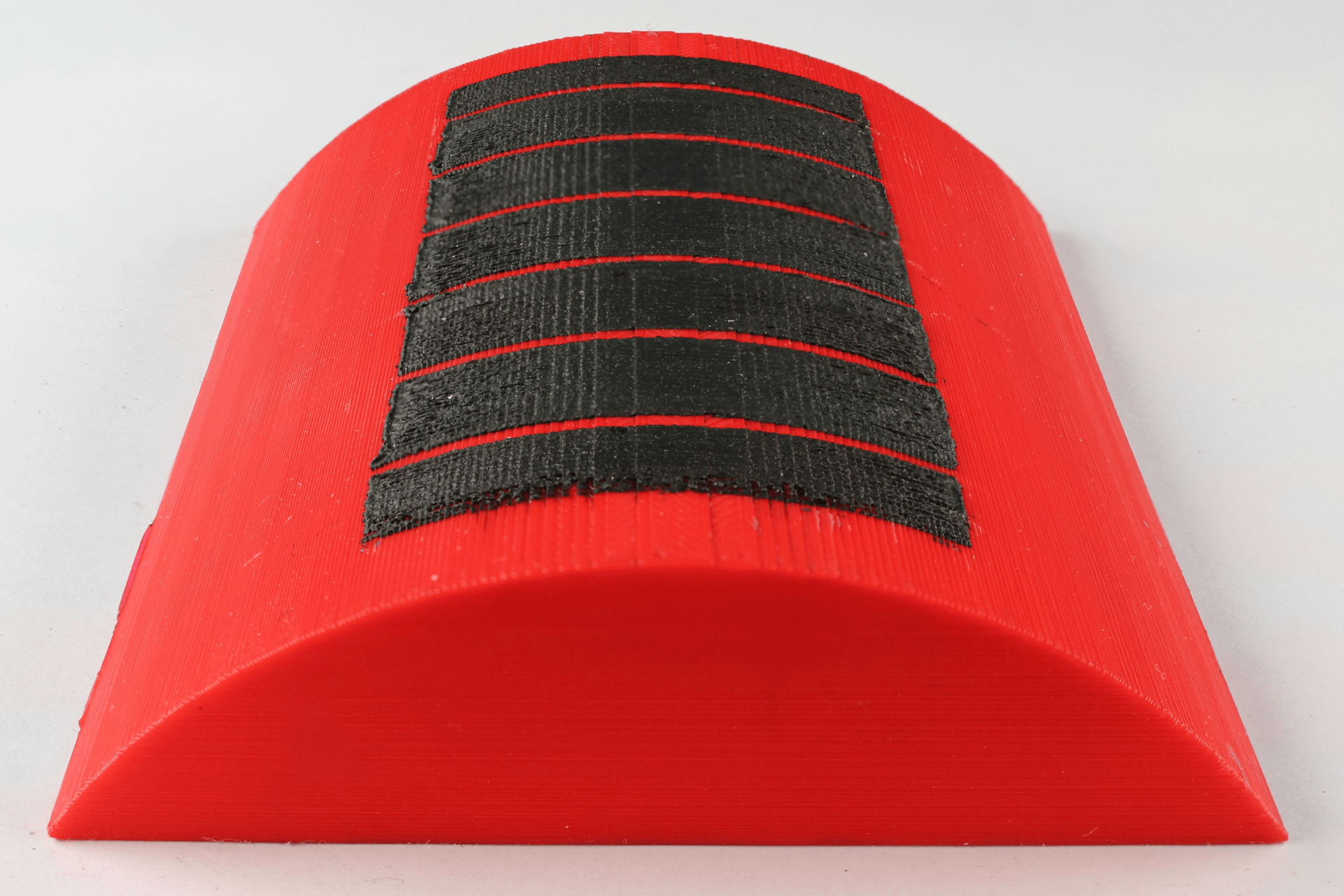

To prove its suitability for making real components, the researchers built, among other things, a strain sensor: a thin strip of PET with a pattern of ink printed on it, the electrical resistance of which changed with great precision according to various degrees of bending.

Furthermore, tests for tensile strength, stability in water and other properties have shown promising results, and so the research team of theEMPA he is confident that the new material, which has already been patented, could prove ideal in practice.

“We hope this ink system can be used for applications in sustainable printed electronics”he concluded Gustav Nystrom.

“This applies, for example, to conductive traces and sensory elements in smart packaging and biomedical devices or in the field of food and environmental sensing.”

There is a drone that "climbs" trees to protect them

You may also be interested in:

In Alto Adige today EDIH NOI is the new point of reference for AI

4,6 million euros from the PNRR fund will be allocated to Bolzano for services to local companies in the digitalisation of intelligence…

by Editorial staff Innovando.NewsEditorial staff of Innovando.News

Austria, Germany and Switzerland for "more innovative" cargo railways

DACH Ministers Leonore Gewessler, Volker Wissing and Albert Rösti: the introduction of Digital Automatic Pairing is a key element

by Editorial staff Innovando.NewsEditorial staff of Innovando.News

Persuasion or manipulation? Genesis and historical impact of PR

This is how Public Relations, from the sophistic dialogue of ancient Greece to the current digital era, continues to offer continuous innovation

Young people and cryptocurrencies: how to find out more about Bitcoin…

Introducing kids to digital currencies and Blockchain can be an exciting endeavor, given their affinity for technology and innovation